Toll Free: 1-866-508-6394

OR Contact Us

OR Contact Us

Shop by Category

| Custom Constructed Torsional Test Machine Featuring:- Loading capabilities between 1,000 ft/lbs and 15,000 ft/lbs - Versatile “real world” fixturing options | |||

| The MW Torsion testing machine can help your project verify and solve shaft strength issues. Our machine is used to fail test and proof test a variety of our products and we now offer the same testing as a service. Almost any type of torsional testing can be performed, from failure to fatigue life. Whether you need to test a driveshaft, splined shaft, axle, or anything to verify torsion strength, we can help. The machine’s normal operating range is 1,000 to 15,000 ft/lbs torque range and can perform cycle tests at speeds up to 2 cycles per second. We can customize programs for cycle test routines that use torque or degrees of deflection as test limits. Samples of shafts that have a failure problem can be tested in a variety of ways to help pinpoint the source of failure. The type of testing and the types of fatigue testing can be easily matched to your needs. If requested we can recommend design improvements and re-test the improved product before returning your product to a service environment. If custom tooling and fixturing is required, it can be built in house or we can supply designs for you to produce your own fixturing. Call us today to see what we can do for you! | ||||

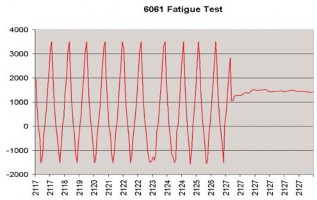

Fixturing for ultimate strength test of carbon fiber drive shaft | Aluminum Driveshaft Fatigue Test | |||

| ||||

Torsion Testing Examples | ||||

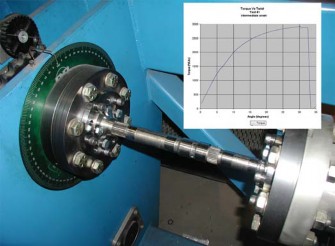

Aluminum Driveshaft Failure Test -featuring real world simulated fixturing. The driveshaft shown was an ultimate strength test performed to determine strength at the weld. The fixturing used mimics the parts used in a typical race car allowing us to replicate conditions the driveshaft would be exposed to in real world applications. |  | |||

| Removing the guess work is the real advantage to this type of testing. Unkown variables in your design can be tested in situations that traditional material testing and FEA dont uncover. Material flaws, manufacturing flaws, and misconceptions about running conditions can all be exposed in simulation type testing. | ||||

| Aluminum Driveshaft Failure Test - featuring component isolation. | |||

| Removing one of the failure points in the system, in this case U-Joints, allows for isolation of separate components. Taking advantage of the adaptability of our system allowed for the same test to be run and further isolate design obstacles. | ||||

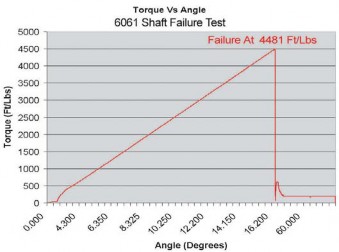

Typical failure test results -Test reults from the shaft pictured above. Thist test was simply loading the part until it experienced a complete failure.  | ||||

Transmission Shaft Failure Test -Splined shafts are a natural for our torsion machine. The fixturing is straight forward to build, and by its nature it mimics running conditions very well. Shafts can be stressed and released at a point before failure as well as a full failure.  | ||||