Toll Free: 1-866-508-6394

OR Contact Us

OR Contact Us

Shop by Category

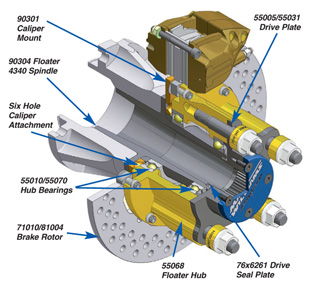

FULL FLOATERS VS. FLANGED AXLESThese days more and more race cars are being built with full-floater rear ends. Clearly that’s good from a safety standpoint, given that in case of an axle failure a wheel cannot come off the car. This factor alone makes a full-floating rear end a wise investment, as there have been many incidents over the years where a wheel coming off has caused an accident leading to significant race car damage . It goes without saying that driver safety is of paramount importance.But what actually makes a “full floater” and how does it differ from a conventional setup with a flange-type axle? On a standard rear end, the axles are manufactured with a flange on the outer end. This flange holds the wheel studs and a single bearing pressed onto the shaft inboard of the flange. This configuration requires the axles to perform several functions. First and most obvious is supporting the weight of the vehicle, but it must also transmit torque from the center section the wheels. But it doesn’t stop there as they are also responsible for driving the car forward. With the tire and wheel being outboard of the axle bearing there are tremendous loads being applied to axle and bearings every time a car leaves the starting line.  These loads can actually cause the rear wheels to toe-in for instant. Going to a larger axle bearing with higher radial load capacity will help with potential bearing issues but will not relieve the axle of the bending forces applied to them. By comparison a “full floater” incorporates a wheel hub with two large bearings, typically spaced 2" to 2 1/2" apart, one at the inside face of the hub and one at the outer face of the hub, directly inside of the wheel studs which are also part of the hub. A floater housing will have a “spindle” in place of a housing end used for flange axles. Assembled floater hubs are installed onto the spindles, the large I.D. of the hub bearings onto the O.D. of the spindle. The axle then runs through the center of the spindle and “floats” between the splines in spool and the splined drive plate. This drive plate is sandwiched between the hub and the wheel and drives against the wheel studs. All of the loads associated with accelerating the car forward are now being handled by the hub and its bearings, leaving the sole function of the axle to transmit torque from the spool to the wheels. Having a “full floater” also pays dividends in reduced maintenance time. When changing a thirdmember on a conventional type 9" Ford rear end you’ll need to pull the brake calipers, rotors and caliper brackets before you can remove the axle and in turn pull the center section. With a full floater it’s simply a matter of sliding the drive plate and axle out. Not having to disturb the brakes eliminates the possibility of a pinched or broken brake line or brake pads being left out or put in incorrectly (don’t laugh it’s been done). Seldom, though, do racers equate a full-floating rear end with improving performance —but they can actually make a car go quicker. As mentioned earlier, flange-type axles can actually toe-in under hard load conditions (high HP, high torque engine) and affect the tracking of the car, robbing E.T. A floater housing is impervious to the torque and the wheels remain perfectly aligned. What’s more, in some applications a full-floater can actually weigh less than a flange-style setup. The only limiting factor of a full floater is the wheel stud patterns available, either 5" x 5 or 5 1/2" x 5. Granted, a full-floater setup is more expensive than a conventional rear end, but for many racers it’s a worthwhile investment in performance, reliability and safety. |

|