Toll Free: 1-866-508-6394

OR Contact Us

OR Contact Us

Shop by Category

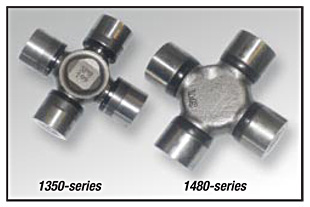

The proverbial “800 pound gorilla” in any race car is torque. Most knowledgeable engine builders know it’s torque that wins drag races—not horsepower. And transmitting the engine’s torque to the ground is largely the responsibility of the driveline. Obviously, getting as much torque to the tires as possible should be the goal of every performance-oriented racer. There are two areas that merit discussion; the actual multiplication of torque through the driveline, and what can be done to maximize it. Determining how much torque is ultimately being exerted is a function of multiplying the engine’s torque by the transmission first gear and rear end gear. So it’s easy to see that in a high-end doorslammer application, like a Pro Stocker, well over 10,000 foot pounds of torque (5,000 to each wheel) are what’s making the car launch and accelerate.  The first order of business is to make sure that the driveline components are up to the task, remembering that the car’s weight will affect overall reliability. For example, given the shock load of applying this kind of torque to the rear end gear you’ll want a 9310 alloy “Pro” gear as opposed to the “softer” 8620 material—although lighter cars, like dragsters, can get away with it. Then there’s the driveshaft. For openers, 1350-style U-joints have proven to be capable of handling Pro Stock-type torque. When power-adders, such as superchargers, turbos and nitrous oxide are introduced, an upgrade to 1480-style U-joints is recommended for Pro Mod torque levels. Then there’s the shaft itself, which can be made of steel, aluminum or carbon fiber. Determining the optimum material, shaft diameter, etc. is a subject onto itself. But suffice to say that Mark Williams Enterprises has a Torsional Testing Device that can exert in excess of 20,000 ft. lbs. of torque and knows what works best for a given application. This device is also used to validate SFI 43.1 driveshaft specs. Now, how do you maximize torque output? There are parasitic forces at play in several areas, and there are ways to minimize them. For example, utilizing a surface treatment on the ring and pinion gears will cut down on friction and also improve the service life of the gear set. M-W’s in-house REM process is called “Supra-Fin” and can be applied to any new gear set (you cannot process used gears as it will exacerbate wear patterns).  Increased efficiency can be obtained through micro-polishing gears. Shown here is M-W’s Supra-Fin™ process. The rear end housing itself is a prime area for reducing friction, as even the slightest misalignment of the pinion ring gear, spool, axle, bearing or housing end can have detrimental effects. Use of a modular alloy housing, where all tolerances are tightly maintained, assures proper component alignment and optimum efficiency. to provide sufficient clearance for the transmission to be removed without disturbing the engine or rear end. It’s only available for “Shorty” Powerglides. A graphic example of driveline efficiency comes from pushing cars in the pits or rotating the rear wheels when the car is on jackstands; some are real easy and some require a lot more effort. And that “drag” can cost you races.

|